Basically we are going to suggest that the ICAD 1200 is changed, (got to start somewhere!)Īlthough it could be the EKC 347 controller?Īll settings check out and the level probe I think is a AKS 41?Ĭome to think! Ranger, don't you close the valve fully and then open 1 turn when setting them up? The issues have been going on for several weeks but are getting more and more frequent. The settings are factory reset and the valve recalibrates. Historically I have always assumed that when you interrupt the power supply. As I had to attend site earlier and used i26 setting to recalibrate the ICAD. I will let you know regarding the recalibration. So no power cuts, ICAD shows 100% but is actually closed? Well at least until the standing pressures have equalised then you have to create a HP /LP differential to further fill the drum.

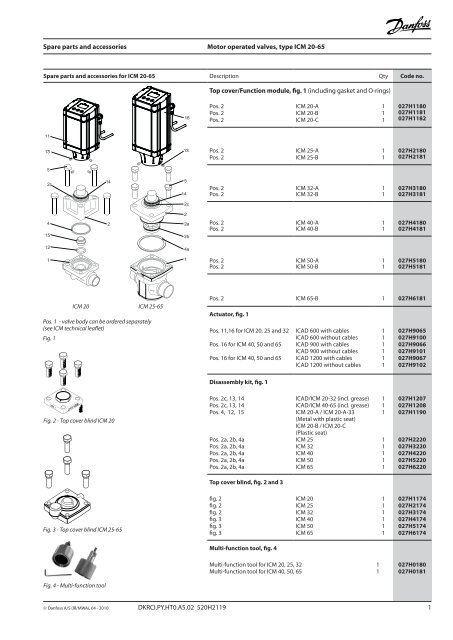

Once onsite the valve opening is shown as 100% open but is actually closed.īecause the refrigerant level in the receiver is high and opening the Liquid Line bypass.Īllows the refrigerant to flood into the surge drum. "Is a right Pain in the butt, Particularly if the plant room is on the ground floor and the control room is 1st floor! Resulting in long shutdowns before anyone on-site notices the chill room temps rising.Īs anyone will appreciate once emptied getting a large Ammonia plant away again is, Shall we say Said valve has started to randomly shut closed and the surge drum gradually empties.Ĭausing the plant to cycle off on it's suction Pressure control. With it's liquid level being metered by a ICAD /ICM Valve.

A site (Un manned by Engineers) has a large surge drum on Ammonia.

0 kommentar(er)

0 kommentar(er)